Order your no-risk XP-3D Intro Kit today

The XP-3D Shaper+ is the next generation of our adaptive XP-3D line, created for shorter procedure times and agility. It addresses the shortcomings of traditional NiTi instrumentation and ushers in a new biologic standard of care in endodontic instrumentation. The XP-3D Shaper+ is a totally unique system that offers predictability, superior resistance and the ability to use multiple times in initial treatment, giving it the added advantage of shorter procedure times.1, 2

The patented XP-3D Shaper+ safely, efficiently and effectively cleans the root canal system three dimensionally while respecting the canal anatomy. As it rotates, the instrument’s orbit expands and contracts to abrade the broad and narrow aspects of the canal equally. This intuitive micro mechanical debridement allows the practitioner to utilize a single instrument to safely and efficiently clean and enlarge the canal while respecting the original canal morphology.

SIZE & EXPANSION CAPACITY

The XP-3D Shaper+ is an ISO #30 with a 1° taper. Its adaptive core design allows it to adapt to canal morphology ranging from size #30 to size #90 at a .02 to .08 taper.* The flexible core gently pulsates within the root canal as it spins, continually adapting to the canal’s natural anatomy.**

MAXWIRE®

- Super elasticity, extreme flexibility and resistance to cyclic fatigue

- Transformation to a robust, predefined serpentine shape at body temperature 95°F (35°C)

- Ability to gently expand to the natural anatomy of the root canal

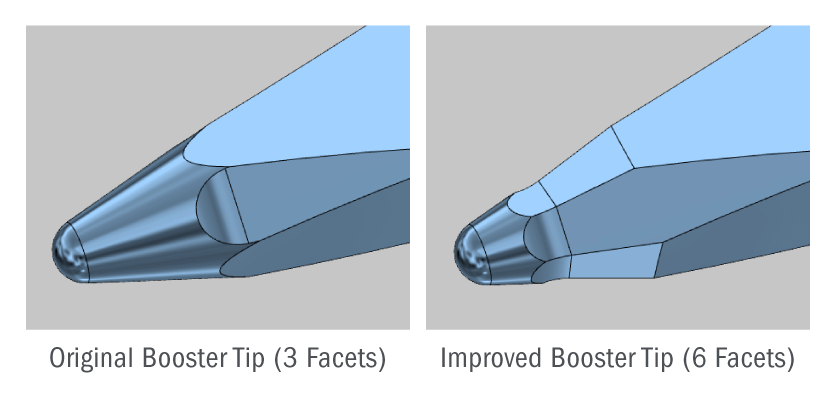

BOOSTER TIP™

- Six facets and cutting edges for optimal guidance and scouting

- Shaping begins at ISO #15 and transitions to ISO #30

- Tip transitions from six to three cutting edges to improve the clearing of debris

ADAPTIVE CORE™ TECHNOLOGY

The XP-3D Shaper features unique Adaptive Core Technology which allows the smaller central core of the file to move freely and adapt to the canals natural morphology. This facilitates debris removal, making it more efficient without occluding the dental tubules. Furthermore, the turbulence generated by the XP-3D Shaper enhances the penetration of irrigants into dentinal tubules and improves the overall disinfection of the canal.

*Patent Pending

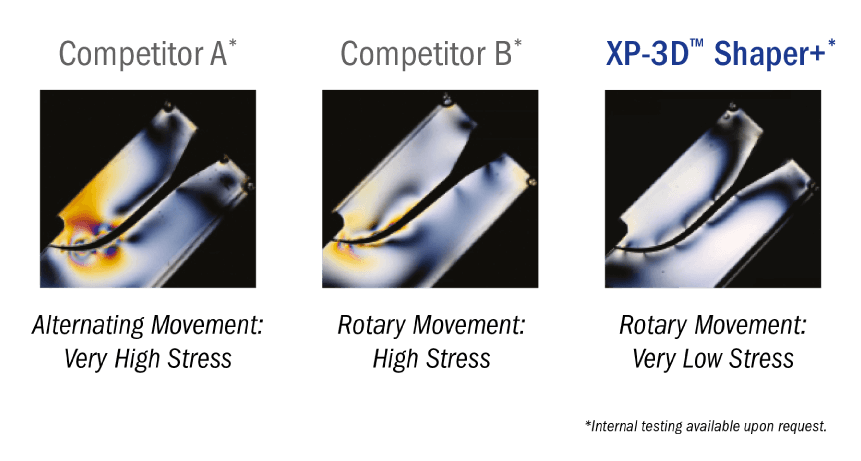

GENTLE, LOW-STRESS MECHANICAL DEBRIDEMENT

The XP-3D Shaper’s design characteristics drastically limit the amount of torque and stress applied to both the instrument and the canal. This results in reduced instrument separation and dentinal micro-cracks.

The below graph shows the result of a test performed on plastic blocks demonstrating the average torque generated by three instruments during canal treatment.

The images below show the result of a photoelasticity test performed on plastic blocks to illustrate the stress applied by instruments during canal treatment. The greater the stress, the higher the risk of micro-cracks and instrument separation.

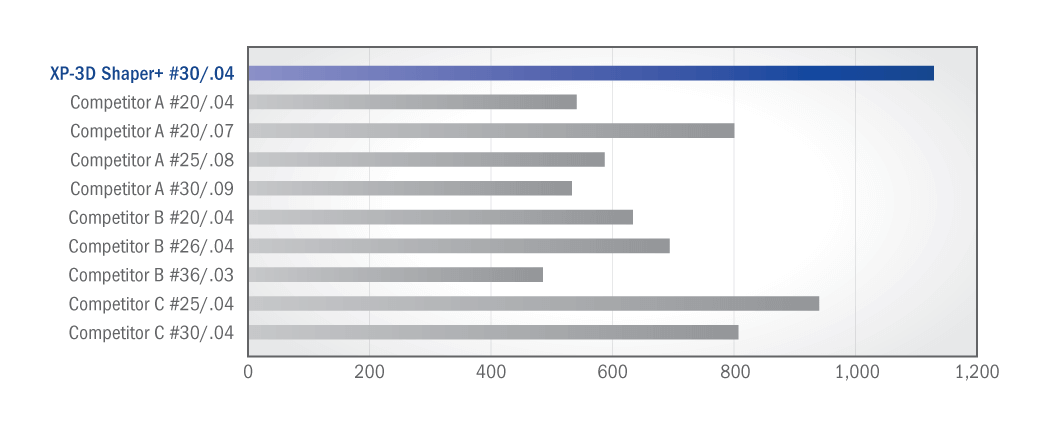

SUPERIOR RESISTANCE & FLEXIBILITY

The below graph shows the mean number of cycles to fracture.†

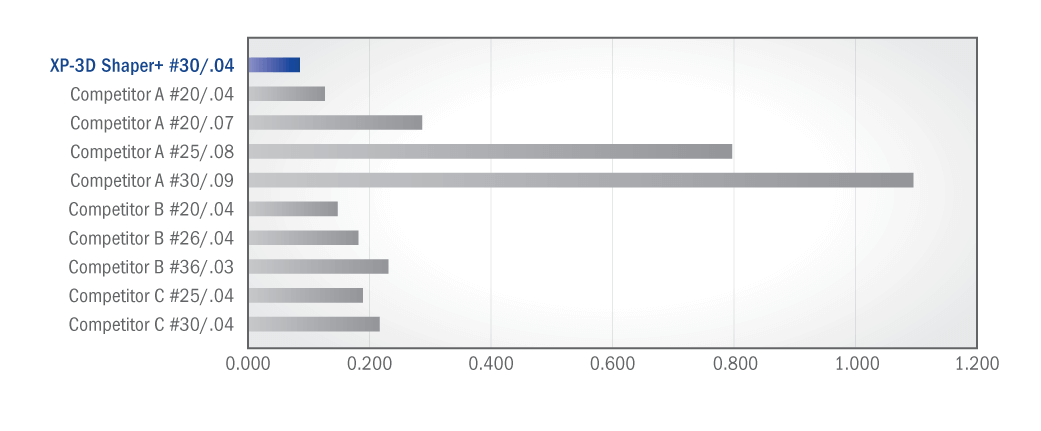

The following graph shows the mean torque (Ncm) required to bend at a 45° angle. Less torque required means more flexibility.†

The XP-3D Instruments usher in a new biologic standard of care in endodontic instrumentation

Case Studies

CASE STUDY #1

Canal preparation (ex-vivo) of a maxillary right first premolar to size 30/.04 with the XP-3D Shaper then filled with EndoSequence® BC Sealer™ and EndoSequence® BC Points™. We can see that the original shape of the canal has been perfectly preserved.

© Dr. Hubert Gołąbek (Poland) and Dr. Martin Trope (USA). All rights reserved.

CASE STUDY #2

A 62 year old woman presenting with symptomatic pulpitis on the upper right first molar. After preparing a glide path to 15/.02, the canals were instrumented with the XP-3D Shaper to 30/.04 following the instructions for use. The canals were then obturated with EndoSequence® BC sealer™ and EndoSequence® BC Points™.

© Dr. Kleber K.T. Carvalho (Brazil). All rights reserved.

CASE STUDY #3

Pulpectomy performed on lower right first molar. After preparing a glide path, the five canals were instrumented with the XP-3D Shaper. The canals were further cleaned with the XP-3D Finisher and obturated with EndoSequence® BC Sealer™ and EndoSequence® BC Points™.

© Dr. Gilberto Debelian (Norway). All rights reserved.

1 Azim AA, Piasecki L, da Silva Neto UX, Cruz ATG, Azim KA. XP Shaper, A Novel Adaptive Core Rotary Instrument: Micro-computed Tomographic analysis of Its Shaping Abilities 2017;43(9):15321538.doi:10.1016/j.joen.2017.04.022

2 AlOmari T, Mustafa R, Al-Fodeh R, El-Farraj H, Khaled W, Jamleh A. Debris Extrusion Using Reciproc Blue and XP Endo Shaper Systems in Root Canal Retreatment.Int J Dent.2021;2021:6697587. Published 2021 Mar 24.doi:10.1155/2021/6697587

* For roots above size #30, the natural apical anatomy will be maintained. Taper increases ~.02 degrees with every ~10 gentle strokes. The typical taper created with XP-3D Shaper+ is .04.

**For maximum 3-dimensional cleaning potential consider also using the XP-3D Finisher.

†Internal testing available on request.